Sprayer upkeep issues.

When Washington State College regional extension specialist Gwen Hoheisel talks about investing in gear to economize on spraying, she just isn’t speaking about pc imaginative and prescient methods, good expertise or lidar. She means new nozzles, followers that blow the way in which they’re supposed to and gauges you may really learn. Growers might get monetary savings on chemical payments simply by upgrading their nozzles, she mentioned at a discipline day in August close to Prosser.

Present expertise provides extra precision in spraying than ever earlier than. Sensible Apply makes use of lidar sensors that detect cover presence and density after which set off pulse width modulation solenoid valves to regulate nozzle output primarily based on the dimensions and presence of vegetation. Many commercially accessible price controllers modify stress to manage spray charges as tractors velocity up and decelerate.

However even these instruments miss their targets if old-school {hardware} fails.

Hoheisel commonly discusses the necessity for upkeep checks at discipline days and offers ideas for making changes. Listed here are a number of examples of her easy however crucial classes.

Gauges

Ensure you can learn your gauges, Hoheisel mentioned. She likes to point out off one that’s cloudy and obscured. She discovered it on a farmer’s working spray tank one 12 months.

Watch the needle, she added. If it doesn’t return to zero when the sprayer is off, the stress gauge is unhealthy. If it settles at 5 PSI when not in use, don’t simply attempt to do some psychological math while you flip it on. Strain measurement just isn’t all the time linear.

There are methods to check a gauge with an air compressor and a identified working gauge, however it is perhaps best to only substitute it, she mentioned. Even some producers say they’re dependable for just one 12 months.

“It’s a easy factor to resolve to switch your stress gauge yearly; $20 substitute value, you recognize the half is working,” she mentioned.

Nozzles

Nozzles can be changed comparatively inexpensively yearly, Hoheisel mentioned.

However use ceramic nozzles, particularly disc-core nozzles, she mentioned.

The tree fruit and wine grape industries use loads of oil, sulfur and different corrosive supplies, she mentioned. Brass nozzles have a couple of 1 or 2 resistance ratio, a measurement of how shortly materials wears down. Chrome steel improves that by about fivefold, ceramic by a couple of hundredfold.

To scrub nozzles, don’t use sharp instruments, like coat hangers or paper clips. They trigger harm and mess up the spray sample of the nozzle. Use a toothbrush as an alternative.

“Everyone goes to the dentist, and also you get a free toothbrush,” she mentioned. “And if it’s adequate in your enamel, you need to use it in your nozzles.”

Cans of compressed air work, too, she mentioned.

Airflow

Getting air quantity and course right may very well be one in all your largest spray protection enhancements, Hoheisel mentioned. You solely wish to blow droplets into the cover inside one row.

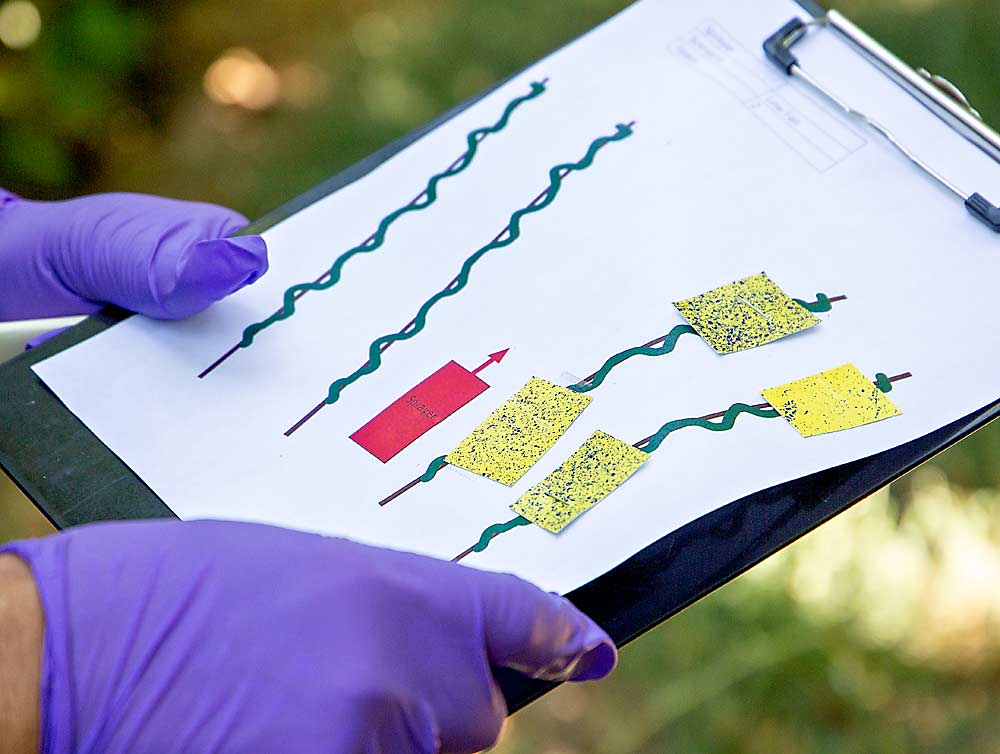

So, earlier than spraying a chemical, check airflow and course of the sprayer array valves.

The spinning movement of axial followers pushes air up on one facet of the sprayer and pulls it down on the opposite. Some sprayers have air straighteners to right for this. Keep in mind, the place air goes, droplets go.

Tie flagging tape to every valve, activate the fan and see if that ribbon billows towards your cover. If not, flip off that nozzle and recalculate the output per nozzle with the intention to keep the identical price per acre, she mentioned. By not drifting into the air, you’ll enhance protection within the cover — the place it issues.

Additionally, tie flagging tape to the again facet of canopies one, two or extra rows away from the sprayer to check how a lot air is blowing via. In case your air quantity is ready too excessive, the ribbons will blow straight out away from the cover. Which means you will miss protection in your goal row. To right that, lower fan measurement, decrease the fan gear field in case you have one, or use the “gear up, throttle down” methodology.

Price management

Price controllers have to be examined. They depend on a sensor, GPS or wheel to measure velocity and modify spray price by altering stress as velocity modifications. These assistance on hilly terrain, however modifications reminiscent of changing underinflated tires can throw off velocity measurements and due to this fact software charges. In the meantime, tractor speedometers are notoriously inaccurate.

Hoheisel advised utilizing an train app — she likes MapMyRide, a snowboarding and biking tracker — to verify velocity reported on the speed controller display screen matches that of the app. If not, the pc or sensors aren’t calibrated appropriately, and you need to name the vendor that can assist you make an adjustment.

—by Ross Courtney